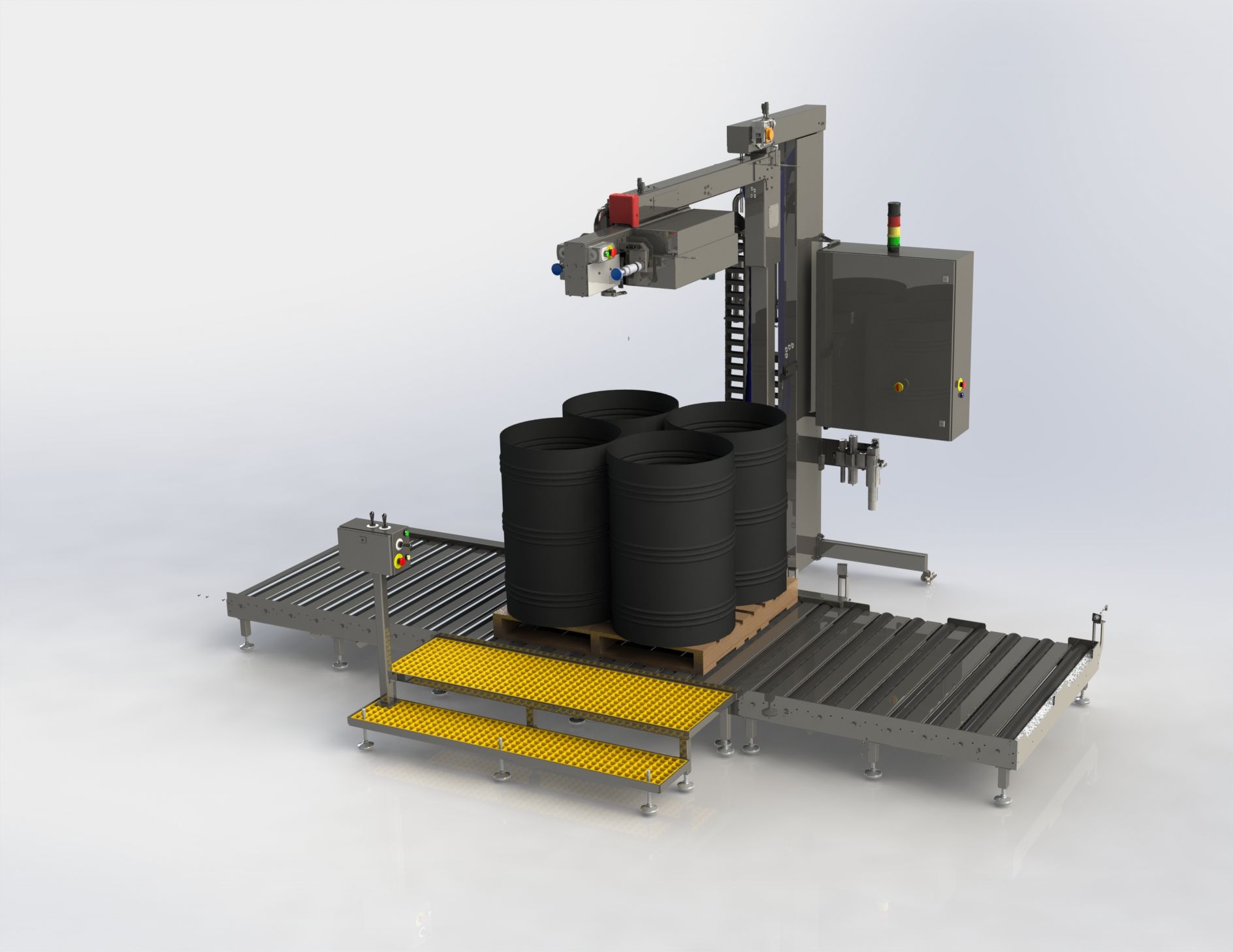

Drum Filler Machine

Engi-O is at the forefront of providing sophisticated, uncomplicated filling solutions for the Aseptic and ESL (Extended Shelf Life) Bag in Box industry. With decades of experience in designing, developing, installing, and servicing aseptic filling equipment, Engi-O is your trusted partner for all your liquid packaging needs.

This Aseptic bag-in-box Drum Filler A4 is ideal for filling drums of up to 240L. It can also be used to fill small 20L bags or sample bags. Engi-O can provide the conveying arrangement presented and customised to your needs.

Features:

- 2-200L bags

- 316 Stainless Steel components

- 1×1.5″ Magnetic Flow Meter, +/-.5 accuracy

- Optional handheld screen for machine control flexibility

- Autofill and eject routine

- Gemu angle seat valves

- Two hand safety start

- Optional conveying accessory with remote commands

- Bioflex product hose (US 3A standards)

- Height adjustable

Below is an indication of the filling time. This is for a bag with a 32 mm gland and the product being supplied by an asseptic tank pressurised at 1 bar with a flow rate of 3 l/s and a non fill time of 15 s.

| Bag size (L) | Fill Time (s) | BPM | BPH | |||

| 2 | 15 | 4 | 240 | |||

| 20 | 22 | 2.7 | 162 | |||

| 200 | 82 | 0.7 | 42 |

The flow rate may vary according to the viscosity of the product and the temperature at which it needs to be filled.

BPM = Bags per minute.

BPH = Bags per hour.

How You Can Benefit from Our Drum Filler Machine?

- Increased Efficiency: Engi-O's Drum Filler Machine is designed to streamline your liquid packaging process, allowing you to fill drums quickly and efficiently. This can help you save time and resources, allowing you to focus on other aspects of your business.

- Versatility: Our Drum Filler Machine is capable of filling drums ranging from 2 litres to 2000 litres, making it suitable for a wide range of products and industries. Whether you're filling drums with sterile products, oils, syrups, or other liquids, our machine can meet your needs.

- Improved Product Quality: Our Drum Filler Machine is designed to fill drums accurately and consistently, ensuring that your products are packaged to the highest standards of quality. This can help you maintain customer satisfaction and build a reputation for quality and reliability.

- Cost-Effectiveness: Investing in Engi-O's Drum Filler Machine can help you save money in the long run. By increasing efficiency and reducing waste, our machine can help you lower your overall packaging costs and improve your bottom line.

- Compliance: Engi-O's Drum Filler Machine is designed to meet the highest standards of quality and safety. Our equipment undergoes rigorous testing and validation to ensure that it complies with global regulatory requirements, giving you peace of mind knowing that your products are packaged safely and legally.

- Customer Satisfaction: By using Engi-O's Drum Filler Machine, you can ensure that your products are packaged accurately and reliably, leading to increased customer satisfaction. Happy customers are more likely to return and recommend your products to others, helping you grow your business.

- Environmental Responsibility: Engi-O is committed to sustainability and environmental responsibility. Our Drum Filler Machine is designed to minimise waste and energy consumption, helping you reduce your carbon footprint and operate more sustainably.

- Support and Service: Engi-O offers comprehensive after-sales support, including servicing, maintenance, and training, to ensure that your Drum Filler Machine continues to operate efficiently. Our team of experts is available to assist you with any questions or concerns you may have, ensuring that you have a seamless experience with Engi-O.

We understand the importance of cost-effectiveness. That’s why we offer competitive pricing for our Drum Filler Machine, ensuring that you get the best value for your investment. Our transparent pricing policy and flexible payment options make it easy for you to acquire the equipment you need without breaking the bank.

The Cost of Our Drum Filler Machine

Learn More

Frequently Asked Questions

Engi-O’s Drum Filler Machine is suitable for a wide range of industries, including wineries, dairies, pharmaceuticals, olive oil producers, juice manufacturers, and water bottlers, among others.

Engi-O’s Drum Filler Machine is designed to handle a variety of products, including sterile products that are shelf-stable, products requiring refrigeration, and oil and syrup-like products.

Engi-O’s Drum Filler Machine can fill drums ranging from 2 litres to 2000 litres, providing flexibility to meet the needs of different products and industries.

Engi-O’s Drum Filler Machine is built to the highest standards of reliability and performance. Our equipment undergoes rigorous testing and validation to ensure that it meets the highest quality and safety standards.

Yes, as an independent machine manufacturer, Engi-O can assist in selecting the right drum for your products. We work with many drum suppliers and can help you find the best packaging solution for your needs.

Yes, Engi-O offers comprehensive training for operating its equipment. Our team of experts will ensure that your staff are fully trained and confident in using the equipment.

Engi-O offers comprehensive after-sales support, including servicing, maintenance, and training to ensure that your equipment continues to operate efficiently. Our team of experts is available to assist you with any questions or concerns you may have.

GET IN TOUCH

Have questions or need assistance? We're here to help!