- Home

- Aseptic

Aseptic

Providing the best construction policy

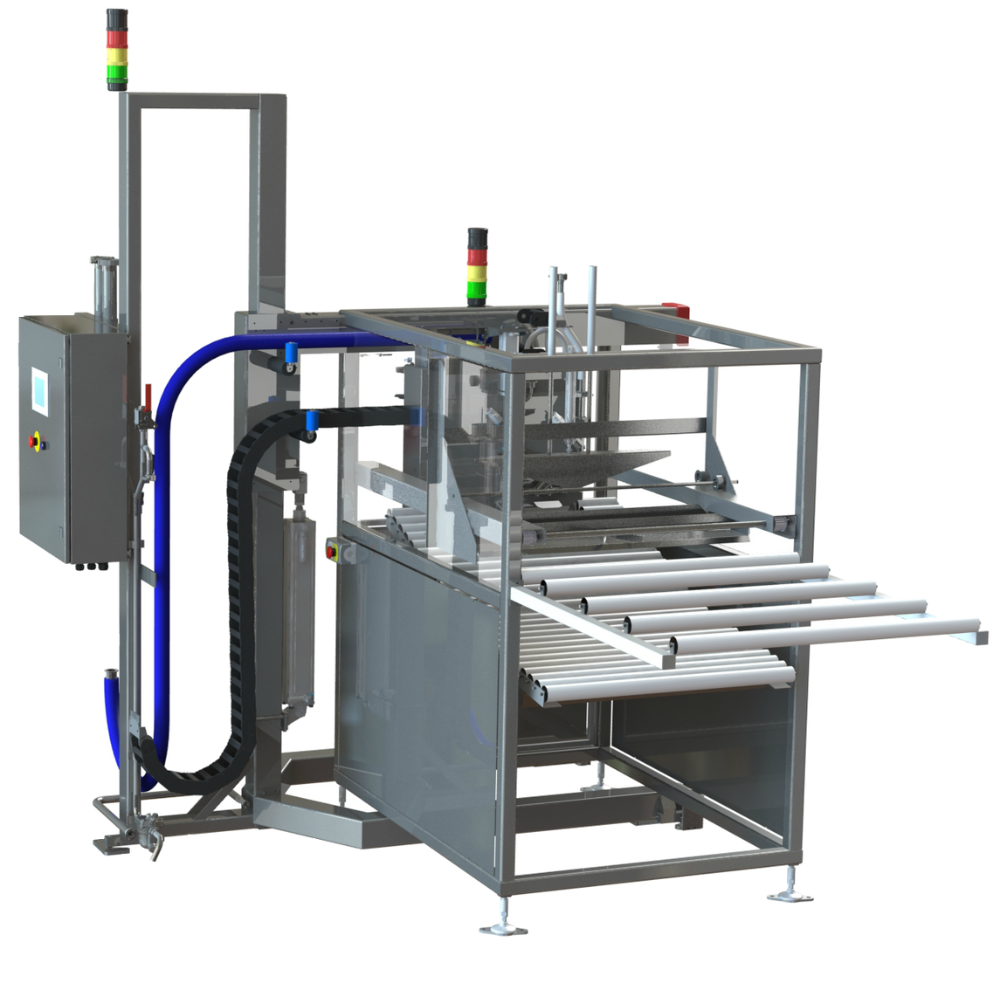

Aseptic Filler Machine

Engi-O is committed to providing sophisticated, uncomplicated filling solutions for the Aseptic and ESL (Extended Shelf Life) Bag in Box industry. With decades of experience in designing, developing, installing, and servicing aseptic filling equipment, Engi-O stands out as a leader in the field.

Your Solution for Safe and Efficient Aseptic Bag Filling

In the world of liquid packaging, aseptic bag filling has become increasingly important. Aseptic filler machines are designed to fill bags with sterile, shelf-stable products, ensuring the highest level of safety and quality. These machines are crucial for industries that require the packaging of sensitive products, such as food, beverages, and pharmaceuticals. These machines are designed to maintain a sterile environment throughout the filling process, preventing contamination and ensuring product integrity. With advanced features like automated cleaning and sterilisation systems, aseptic filler machines minimise the risk of human error and guarantee consistent results.

Read More

One of the key advantages of aseptic filler machines is their versatility. These machines can handle a wide range of bag sizes and fitments, allowing businesses to customise their packaging to meet specific product requirements. From small pouches to large bags, aseptic filler machines can accommodate various packaging formats, making them suitable for different industries and applications.

Investing in an aseptic filler machine is a smart choice for businesses looking to enhance their aseptic bag filling operations. By ensuring product safety, versatility, efficiency, and reliability, these machines offer a comprehensive solution for the packaging needs of various industries. Embracing the technology of aseptic filler machines can help businesses stay competitive in the market and meet the growing demand for safe and high-quality packaged products.

The Need for Aseptic Filler

In the liquid transport industry, it is crucial to ensure that products are packaged safely and efficiently. Engi-O specialises in solutions for sterile products that are shelf-stable, not requiring refrigeration, through to products requiring refrigeration and further to oil and syrup-like products. Our aseptic filling equipment is designed to meet the highest standards of quality and safety, ensuring that your products are packaged safely and effectively.Read More

Check Out Our Aseptic Filler

Engi-O’s aseptic filling equipment has recently passed an independent process authority Food and Drug Administration (FDA) validation in a new installation in North America, highlighting the reliability and effectiveness of our equipment. Our team has developed, designed, and commissioned Aseptic Bag in Box filling machines throughout the world, showcasing our global experience and expertise in the field.The Benefits of Our Aseptic Filling Equipment

Why Choose Us?

- Experience: Engi-O is backed by a team with decades of experience in the design, development, installation, and servicing of aseptic filling equipment. Our team's expertise ensures that you receive top-notch solutions that meet your specific requirements. We have a proven track record of delivering reliable and efficient filling solutions to industries worldwide.

- Innovative Solutions: Engi-O is at the forefront of innovation in the aseptic filling industry. We continuously invest in research and development to bring you the latest technologies and advancements in filling equipment. Our commitment to innovation ensures that you get cutting-edge solutions that are ahead of the curve.

- Customised Approach: We understand that every business has unique needs. That's why we offer customised solutions tailored to your specific requirements. Whether you need a filling machine for sterile products, shelf-stable products, or products requiring refrigeration, Engi-O can design a solution that meets your needs.

- Quality Assurance: Engi-O's aseptic filling equipment undergoes rigorous testing and validation to ensure that it meets the highest quality and safety standards. Our equipment is designed to comply with global regulatory requirements, giving you peace of mind knowing that your products are packaged safely and efficiently.

- Global Reach: Engi-O has a strong global presence, with installations and commissions of Aseptic Bag in Box filling machines throughout the world. Our team is experienced in a variety of global standards, making us a trusted partner for industries worldwide.

- Customer Satisfaction: At Engi-O, customer satisfaction is our top priority. We work closely with our customers to understand their needs and provide them with the best possible solutions. Our dedicated team is always ready to assist you with any questions or concerns you may have, ensuring that you have a seamless experience with Engi-O.

- After-Sales Support: Engi-O offers comprehensive after-sales support to ensure that your equipment continues to operate efficiently. Our team of experts is available to provide servicing, maintenance, and training to keep your filling machine running smoothly.

- Environmental Responsibility: Engi-O is committed to sustainability and environmental responsibility. Our equipment is designed to minimise waste and energy consumption, helping you reduce your carbon footprint and operate more sustainably.

- Certifications: Engi-O's aseptic filling equipment is certified by independent regulatory authorities, including the Food and Drug Administration (FDA), ensuring that our equipment meets the highest standards of quality and safety.

- Competitive Pricing: Engi-O offers competitive pricing for its aseptic filling equipment, ensuring that you get the best value for your investment. Our transparent pricing policy and flexible payment options make it easy for you to acquire the equipment you need without breaking the bank.

Find Out More

Frequently Asked Questions

Engi-O’s aseptic filling equipment is suitable for industries such as wineries, dairies, pharmaceuticals, olive oil producers, juice manufacturers, and water bottlers, among others.

Engi-O’s equipment can handle a wide range of products, including sterile products that are shelf-stable, products requiring refrigeration, and oil and syrup-like products.

Engi-O’s equipment can fill bags/bladders ranging from 2 litres to 2000 litres, providing flexibility to meet the needs of different products and industries.

Engi-O’s equipment is designed and built to the highest standards of reliability and performance. Our equipment undergoes rigorous testing and validation to ensure that it meets the highest quality and safety standards.

Yes, as an independent machine manufacturer, Engi-O can assist in selecting the right packaging for your products. We work with many bag suppliers and can help you find the best packaging solution for your needs.

Yes, Engi-O offers comprehensive training for operating its equipment. Our team of experts will ensure that your staff are fully trained and confident in using the equipment.

Engi-O offers comprehensive after-sales support, including servicing, maintenance, and training to ensure that your equipment continues to operate efficiently. Our team of experts is available to assist you with any questions or concerns you may have.

GET IN TOUCH

Have questions or need assistance? We're here to help!