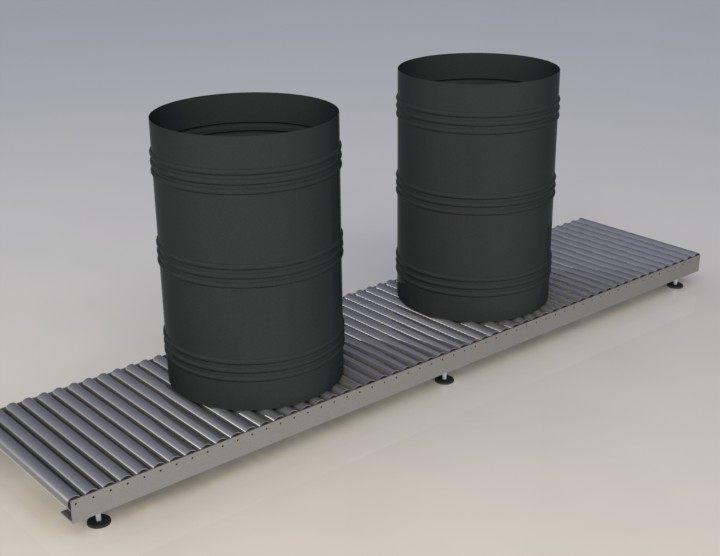

Drum Conveyor

Looking for an efficient way to handle drums in your facility? Engi-O offers a Drum Conveyor designed to streamline the process of moving empty drums under the fill head and away once full. Our gravity-powered conveyor system allows for easy movement of drums, reducing manual handling and increasing efficiency.

Non-powered drum conveyor in order to easily move empty drums under the fill head and away once full. They can then be picked up or pushed onto the pallet for storage.

- Efficient Drum Handling: The use of drum conveyor rollers allows for efficient handling of drums, reducing the need for manual lifting and carrying.

- Increased Productivity: By streamlining the drum handling process, drum conveyor rollers can help increase productivity in your facility.

- Reduced Risk of Injury: Minimising manual handling of drums can help reduce the risk of injuries to workers, improving workplace safety.

- Durable Construction: Our drum conveyor rollers are made from high-quality materials, ensuring long-lasting performance even in demanding environments.

The Advantages of Drum Conveyor Rollers

Why Choose Us?

- Expertise and Experience: Engi-O brings years of experience and expertise in the design and manufacturing of drum conveyor systems. Our team understands the unique challenges and requirements of drum handling and is dedicated to providing innovative and reliable solutions.

- Customised Solutions: We understand that every facility has unique needs and requirements. That's why we offer customised drum conveyor solutions tailored to your specific needs. Whether you need a conveyor for moving drums horizontally, vertically, or at an incline, we can design a system that meets your exact specifications.

- Quality and Durability: Our drum conveyor systems are built to last. We use only the highest quality materials and components to ensure durability and long-lasting performance. Our conveyor rollers are designed to withstand heavy loads and provide smooth and reliable operation.

- Safety and Efficiency: Safety is paramount when it comes to drum handling. Our drum conveyor systems are designed with safety in mind, incorporating features that minimise the risk of injury to operators. Additionally, our systems are designed for efficiency, helping to streamline your drum handling process and improve overall productivity.

- Customer Satisfaction: At Engi-O, customer satisfaction is our top priority. We work closely with our customers to understand their needs and provide solutions that meet or exceed their expectations. Our team is dedicated to providing exceptional customer service and support, ensuring that you have a positive experience from start to finish.

- Reliability and Support: When you choose Engi-O, you can count on reliable performance and ongoing support. Our team is always available to answer any questions or address any issues you may have with your drum conveyor system. We stand behind our products and are committed to ensuring your complete satisfaction.

- Competitive Pricing: Despite offering high-quality products and services, we strive to maintain competitive pricing. We understand the importance of cost-effectiveness in today's competitive market and work hard to provide value for your investment.

Find Out More

Frequently Asked Questions

A Drum Conveyor is a gravity-powered conveyor system designed to move empty drums under the fill head and away once full. It utilises rollers to facilitate the movement of drums, reducing the need for manual handling.

Using a Drum Conveyor can help streamline the process of handling drums, reducing manual labour and increasing efficiency. It also helps to improve workplace safety by minimising the risk of injuries associated with manual drum handling.

Drum Conveyor Rollers are essential components of a Drum Conveyor, providing smooth and reliable movement of drums. They help to reduce friction, allowing drums to move more easily and quickly along the conveyor system.

Yes, Engi-O offers customisable Drum Conveyors that can be tailored to fit specific drum sizes and types. Whether you’re handling steel, plastic, or fibre drums, we can design a conveyor system that meets your requirements.

To ensure the safe operation of a Drum Conveyor, it’s important to follow proper safety procedures and guidelines. This includes providing adequate training for operators, conducting regular maintenance checks, and implementing safety features such as emergency stop buttons and guardrails.

GET IN TOUCH

Have questions or need assistance? We're here to help!

Gravity Drum Conveyor